Have you seen those people who can easily solve any problem that is thrown their way? It’s like problems don’t affect them the same way they affect you. The answer is probably root cause analysis tools.

We all face problems in our lives. Problems at work and problems at home. Wouldn’t it be great to be able to easily solve those problems quickly and effectively?

Root Cause Analysis is the most important step in problem-solving. In this article, you will learn many root cause analysis tools and methods with examples. To eliminate the problem instead of only dealing with the symptoms.

Jump To Section

What Is Root Cause Analysis?

Root cause analysis is a systematic approach used to find the root cause of an issue, taking into consideration all possible contributing factors. It is essentially a problem-solving method that enables managers and leaders to find the conditions that lead to particular results.

Without further ado, let’s get to the root cause analysis methods.

Root Cause Analysis Tools and Methods

The 5 Why’s Root Cause Analysis Tool

This is one of the more popular root cause analysis tools. You can use the 5 Whys for troubleshooting, quality improvement, and problem-solving. However, it is most effective when used to resolve simple or moderately difficult problems.

It may not be suitable if you need to tackle a complex or critical problem. This is because the 5 Whys can lead you to pursue a single track, or a limited number of tracks, of inquiry. When, in fact, there could be many causes. In cases like these, a wider-ranging method such as Cause and Effect Analysis or Failure Mode and Effects Analysis may be more effective.

This simple technique can often direct you quickly to the root cause of a problem. So, whenever a system or process isn’t working properly, give it a try. Before you embark on a more in-depth approach – and certainly before you attempt to develop a solution.

How to Use the 5 Whys

1. Assemble a Team

As you embark on your problem-solving journey, it’s crucial to assemble a team of individuals who are well-versed in the ins and outs of the issue at hand. Your dream team can include those directly affected by the problem or even external consultants who can provide fresh perspectives. Remember, the key to success is to ensure that everyone is on the same page.

To achieve a unified understanding among team members, make sure to clearly communicate the problem you’re tackling and your ultimate objectives. By fostering an environment of openness and collaboration, you’ll lay the groundwork for a successful problem-solving process where everyone’s input is valued and considered. So, gather your team and start working toward effective solutions, together.

2. Define the Problem

To learn more about the problem, analyze the situation. Many problems can be caused by a single situation. Each problem should be identified clearly to help pinpoint the root cause. Anticipate how the people affected by the problem will act.

Based on your first observation, follow these steps to pinpoint the problem:

- Understand the facts and opinions.

- Identify where the problem is occurring.

- Analyze company policies and procedures that may be contributing factors.

- Talk to the team members concerned to get more information.

- Describe the problem in detail

- Collect all information necessary to resolve the problem.

When defining a problem, it is important to stay focused on the problem and not try to find a solution. For example, the problem may be too many orders to fill before the deadline. Saying we must hire more people to fill the orders is focusing on a solution.

3. Ask “Why?”

With the problem clearly defined, it’s time for you and your team to delve into the first “why.” Why is this issue occurring? Though it may appear simple at the outset, there’s usually more to it than meets the eye. Asking “why” serves as a powerful tool for unearthing root causes and guiding your team toward effective solutions.

As you explore the reasons behind the problem, remember to stay grounded in facts rather than conjecture. By avoiding speculation, you’ll prevent your team from getting lost in a maze of irrelevant information and potential distractions. Keep your focus sharp, and you’ll be well on your way to identifying the true causes and finding the best solutions.

4. Dig Deeper With Four More whys

Ask four more “Why’s” for each answer you have generated in the previous step. Frame the question according to the answer that you have just got. For example, if your first question was “Why was I late to work?” Your answer might be “Because I overslept” Your next question would be “Why did I oversleep?”

There can be many answers to any of the questions in the “why” process. For instance, when you answer “Why did I oversleep”, the answer might be because you were tired and your alarm didn’t go off. This can take you down many paths to many root causes.

5. Know When to Stop

When asking “why?” produces no useful answers, you will know you have identified the root cause of your problem. The root cause of the problem should be identified and a countermeasure or process should be clear.

Be careful not to get too far into the weeds with your questioning. When you go too far with asking why you actually begin to move further away from your problem. You get into matters that don’t truly relate to your problem.

6. Discuss the Root Cause(s)

Congratulations, you’ve successfully identified the root cause! With this valuable insight in hand, it’s time to gather your team and strategize ways to not only address the issue now but also prevent its recurrence in the future. Encourage open communication and creative thinking, as this will pave the way for innovative and effective solutions.

As you focus on resolving the root cause, don’t forget to revisit any lingering symptoms of the problem. Tie up those loose ends to ensure a comprehensive and lasting solution. By tackling both the cause and its effects, you and your team will create a solid foundation for continued success and a future free from this particular issue.

7. Monitor Your Measures

Upon implementing your carefully devised countermeasures, it’s essential to keep a close eye on the results. Monitor the effectiveness of your solutions in addressing the original problem. Are they succeeding in eliminating or minimizing the issue? Be prepared to modify or even replace these countermeasures as necessary, ensuring that the problem stays under control.

Stay vigilant and adaptive, as problems can sometimes resurface or countermeasures might lose their effectiveness over time. If this happens, don’t hesitate to revisit the 5 Why’s process from the beginning. This approach allows you to continually refine your solutions and keep your finger on the pulse of the issue, ensuring long-term success and a problem-free future.

Simple 5 Why Example

Problem: I was late to work.

- Why 1: Why was I late to work? I slept through the alarm.

- Why 2: Why did I sleep through my alarm? I went to bed too late.

- Why 3: Why did I go to bed so late? I was up late working on a project for work that is due to management today.

- Why 4: Why was I working on the project at home? I didn’t have time to finish it at work.

- Why 5: Why didn’t I have time to finish the project at work? I was busy helping a coworker meet their deadline on a project they needed help with.

- Possible solution: Next time this happens, have another coworker help the employee. That way I can focus on my tasks and not have to work late into the night to get them done.

Pros of the 5 Whys Technique

- Simplicity: The 5 Whys technique is easy to understand and apply, making it accessible to teams with varying levels of experience. It doesn’t require complex tools or specialized knowledge, allowing for quick problem identification and resolution.

- Cost-effective: Since it doesn’t require any specialized software or equipment, the 5 Whys technique can be implemented with minimal resources, making it a cost-effective approach for organizations of all sizes.

- Promotes collaboration: The 5 Whys technique encourages discussion and collaboration within teams, as members work together to identify the root cause of a problem. This promotes a culture of open communication and shared responsibility.

- Focus on root causes: By continually asking “why,” the 5 Whys technique helps teams dig deeper into a problem, moving beyond surface-level symptoms to uncover the underlying issues that must be addressed for long-term resolution.

Cons of the 5 Whys Technique

- Subjectivity: The 5 Whys technique can be subjective, as it relies on individual interpretation and judgment, which can lead to biased or incomplete conclusions. This limitation can be mitigated by involving a diverse group of stakeholders in the process, ensuring multiple perspectives are considered.

- Limited scope: The 5 Whys technique tends to focus on a single root cause, which may not always be sufficient for complex problems with multiple contributing factors. In such cases, a more comprehensive root cause analysis method may be needed.

- Assumption of linear causality: The 5 Whys technique assumes a linear cause-and-effect relationship between the identified problem and its root cause, which may not always be accurate. Some problems may have multiple root causes or be influenced by interrelated factors that cannot be reduced to a single cause.

- Potential for oversimplification: The simplicity of the 5 Whys technique can sometimes lead to oversimplification of the problem, resulting in superficial solutions that fail to address underlying issues. To avoid this pitfall, it’s important to validate the identified root cause through data analysis and cross-functional input.

Change Analysis/Event Analysis Method

Simple Change Analysis is a tool that can be used to analyze changes in a process. It can help you to understand how the change has impacted the performance of your process and identify any issues that may have arisen as a result of the change.

Simple Change Analysis is particularly useful when:

- You need to determine whether or not an improvement initiative has had the desired effect on your processes and systems

- You want to know what impact new technology will have on existing workflows

- You’re looking for ways of improving efficiency within an organization

How to Use Simple Change Analysis

To use Simple Change Analysis, you’ll need to identify the problem. This can be a specific issue or an area of concern that you want to improve on. Next, work backward from the present state of affairs by examining what has changed since it was created. List out all changes made over time and determine if they were necessary or not. If they weren’t necessary, then it’s likely that one or more problems exist within your system or process that need fixing before moving forward with any new initiatives or projects

Simple Change Analysis/Event Analysis Examples

A production supervisor at a factory notices production has slumped over the past couple of months by 30 percent. The supervisor begins thinking back to what has changed in the past couple of months. The company got a new packaging machine, but that should be able to handle 20 percent more than the old machine. After talking to some employees, the supervisor realizes there is a significant learning curve with the new machinery causing the delay. The supervisor implements some new processes and has everyone trained on the new machinery. This increases the production by 20 percent over the levels before the new machinery.

Pros of Change Analysis/Event Analysis

- Effective in identifying root causes: The Change Analysis/Event Analysis Tool is effective in identifying the root cause of a problem. It helps in analyzing the events that occurred before and after the change, which helps in pinpointing the exact cause of the problem.

- Reduces the time and cost of problem-solving: By identifying the root cause of a problem, the Change Analysis/Event Analysis Tool reduces the time and cost of problem-solving. It helps in quickly identifying the root cause of the problem, which leads to faster resolution.

- Improves system performance: By identifying the root cause of a problem, the Change Analysis/Event Analysis Tool helps in improving the system’s performance. It helps in identifying the changes that need to be made to prevent the problem from occurring again in the future.

- Provides insights for future changes: The Change Analysis/Event Analysis Tool provides insights for future changes. By analyzing the events that occurred before and after the change, it helps in identifying the changes that need to be made in the future to prevent similar problems from occurring.

Cons of Change Analysis/Event Analysis

- Requires expertise: The Change Analysis/Event Analysis Tool requires expertise to use effectively. It requires knowledge of the system and the events that occurred before and after the change. If the person using the tool does not have the required expertise, the analysis may not be accurate.

- May take time: The Change Analysis/Event Analysis Tool may take time to provide results. It requires analyzing the events that occurred before and after the change, which may take time to complete.

- May not identify all root causes: The Change Analysis/Event Analysis Tool may not identify all root causes of a problem. It only analyzes the events that occurred before and after the change. If there were other changes made to the system that were not analyzed, it may not identify all root causes.

- May not be effective in all situations: The Change Analysis/Event Analysis Tool may not be effective in all situations. It is particularly useful when a problem occurs after a specific change has been made. However, it may not be effective in identifying the root cause of problems that occur randomly.

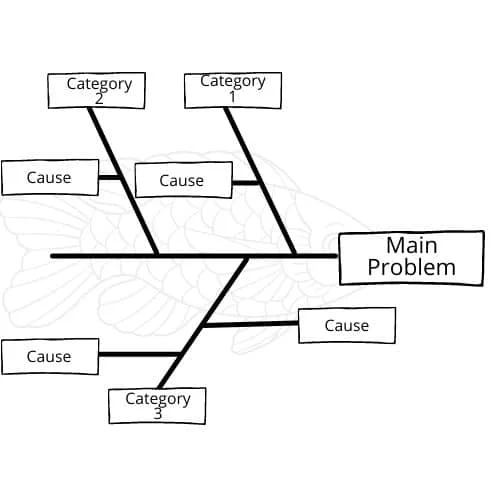

Cause and Effect Fishbone Diagram (Ishikawa Diagram)

Another technique to visually map cause and effect is the creation of a Fishbone diagram (also known as an Ishikawa Diagram). This technique can be used to find potential causes of a problem. It encourages us to follow categorical branches to possible causes until we find the right one. This is like the 5 Whys, but more visual.

We usually start with the problem at the center of the diagram (the fish skeleton’s spine), then brainstorm a few potential root cause factors. These are then put in off-shooting branches (the fish skeleton’s rib bones). The categories can be very broad and could include “People” or even “Environment.” Once we have grouped the categories, we then break them down into smaller pieces. We might, for example, consider root causes such as leadership, staffing, or training under the heading “People”.

We can get closer to the real root cause of the problem by digging deeper into possible causes and sub-causes. This method can be used to eliminate unrelated categories, find likely root causes, and determine correlated factors. Make sure you choose the right categories before beginning this effective root cause analysis method. This will help keep it simpler.

How to Use The Cause and Effect Fishbone Diagram

- Define your problem just like in the “5 Why’s”. Put this in the mouth of your diagram.

- Choose the major categories. These will be the branches of your diagram. Categories should be general things like people, equipment, resources, etc.

- Once categories are selected, start brainstorming possible causes. Put them under the correct category as a new branch.

- Like the “5 Why’s”, you ask why each cause is happening to create sub-causes. These will be branched off the main cause. You do this until you get to the root of the causes.

- Once root causes are determined, you should have some actionable solutions to your problem. Decide which solutions can and should be implemented or researched further.

Pros of Cause and Effect Fishbone Diagram

- Visual representation: The Fishbone Diagram provides a clear and concise visual representation of the potential causes of a problem, making it easy to understand and communicate with others. The diagram can help teams quickly grasp the complexity of a situation and identify areas for further investigation.

- Promotes brainstorming and collaboration: The process of creating a Fishbone Diagram encourages team members to brainstorm and collaborate, as they work together to identify potential causes of a problem. This fosters a sense of shared ownership and responsibility and can lead to more innovative solutions.

- Organizes information: The Fishbone Diagram categorizes potential causes into distinct groups, such as people, processes, equipment, and materials. This organization helps teams to focus their efforts on specific areas and can help to identify patterns and relationships between causes.

- Versatile: The Fishbone Diagram can be used in various industries and for different types of problems, making it a versatile tool for root cause analysis. It can be adapted to suit the specific needs of a team or organization.

Cons of Cause and Effect Fishbone Diagram

- Subjectivity: The Fishbone Diagram is a subjective tool, as it relies on individual opinions and judgments to identify potential causes. This may lead to biased or inaccurate conclusions if not approached with care. Involving diverse perspectives and validating potential causes with data can help mitigate this limitation.

- Complexity: While the Fishbone Diagram provides a visual representation of potential causes, it can become complex and difficult to analyze if there are numerous contributing factors. In such cases, a more structured root cause analysis method may be required.

- Does not prioritize causes: The Fishbone Diagram does not inherently prioritize potential causes, making it difficult to determine which areas to focus on for further investigation or improvement efforts. Teams may need to use additional tools, such as the Pareto Analysis, to prioritize identified causes.

- No guarantee of identifying root cause: Although the Fishbone Diagram can help identify potential causes of a problem, it does not guarantee that the actual root cause will be found. Teams may need to conduct further investigation and analysis to confirm the root cause.

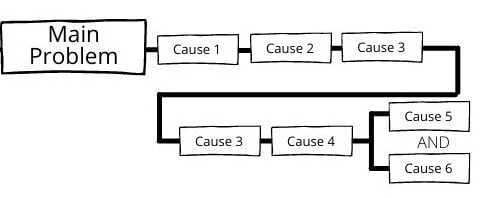

Cause Mapping Method

A cause map is like a Cause and Effect Fishbone Diagram. It is a form of visual representation of problem analysis. Both can use the “5 Why’s” approach to dig deeper into causes.

The difference is the cause map reads from left to right as opposed to the Fishbone Diagram reading from right to left. This is the case because the Fishbone diagram was invented in Japan, and they read from right to left.

Also in the Fishbone Diagram, causes are broken down into categories. This is not the case for cause mapping.

With cause mapping, there may also be causes linked with an “and”. For example, I couldn’t pay my rent because my paycheck was smaller than usual, and I had to pay hospital bills.

How to Use Cause Mapping

- Like all the other methods, the first step is to define your problem. This goes on the left.

- Next, ask why. This cause or causes go in a box to the right of the problem.

- Continue asking why to dig deeper for each cause until you have reached at least five levels of causes.

- This should give you at least one actionable approach to solving the original problem.

Pros of Cause Mapping Method

- Simplifies complex problems: The Cause Mapping Method breaks down complex problems into smaller, manageable parts, making it easier for teams to understand the underlying issues and identify the root causes.

- Visual representation: By creating a visual map of cause-and-effect relationships, the Cause Mapping Method allows teams to see the connections between various factors, facilitating a better understanding of the problem and promoting clearer communication among team members.

- Systematic approach: The Cause Mapping Method follows a structured, step-by-step process that encourages teams to be thorough in their analysis. It ensures that all potential causes are considered and helps prevent the overlooking of critical factors.

- Versatility: The Cause Mapping Method can be applied to a wide range of industries and problem types, making it a flexible and adaptable tool for root cause analysis.

Cons of Cause Mapping Method

- Time-consuming: The Cause Mapping Method can be time-consuming, particularly for complex problems with multiple potential causes. This may not be suitable for situations where a quick resolution is needed.

- Requires expertise: To effectively use the Cause Mapping Method, team members must have a strong understanding of the problem and the ability to identify cause-and-effect relationships. This may require training or the involvement of experts, which can be a limitation for some organizations.

- Subjectivity: Similar to other root cause analysis tools, the Cause Mapping Method can be subjective, as it relies on individual opinions and judgments to identify potential causes. Ensuring diverse perspectives and validating potential causes with data can help mitigate this limitation.

- Limited by available information: The accuracy and effectiveness of the Cause Mapping Method are dependent on the quality and availability of information. If crucial data is missing, the resulting analysis may be incomplete or inaccurate.

Understanding Fault Tree Analysis

An excellent tool for root cause analysis is Fault Tree Analysis (FTA). We’ll break it down step by step. This method helps you figure out why things go wrong and how to stop them from happening again.

What is Fault Tree Analysis?

Fault Tree Analysis is a helpful way to see how different problems can lead to one big issue. It’s like a map that shows cause and effect. This helps you understand the connections between smaller problems and the main failure.

How to Create a Fault Tree

Creating a fault tree involves these steps:

1. Define the Problem

First, get clear on the main issue you want to solve. This is your starting point.

2. Identify the Causes

Think about possible causes. Break those down into smaller parts. Ask why things happen.

3. Build the Tree

Start with your main problem at the top. Below it, list the causes. Use lines to connect them. Keep breaking down each cause until you reach the root.

4. Analyze the Tree

Look at your tree. Find the easiest fixes. Identify the steps that will best prevent the problem from happening again.

Pros and Cons of Fault Tree Analysis

Like any tool, FTA has its strengths and weaknesses. Understanding both will help you use it effectively.

Pros

1. Clear Visualization: FTA helps you see the connections between different problems. This makes it easier to understand complex issues.

2. Focuses on Prevention: It shows you the root causes, so you can fix the issue and prevent it from happening again.

3. Systematic Approach: FTA provides a step-by-step method. This makes the process organized and thorough.

4. Versatile Application: You can use FTA in various fields, from engineering to healthcare.

Cons

1. Time-Consuming: Creating a detailed fault tree takes time. It requires thorough analysis and careful thinking.

2. Requires Expertise: You need some knowledge to effectively build and analyze the fault tree. New users might need training.

3. Complex for Large Systems: For bigger systems, fault trees can get very complicated. This might make them harder to manage and understand.

4. May Miss Unseen Factors: FTA focuses on known causes. It might not account for unexpected or unknown issues.

Why Use Fault Tree Analysis?

Using FTA is crucial because it saves time and resources. It helps you focus on the most important fixes. This approach is practical and can be used in many situations.

Finding Your Own Solutions

Remember, each problem is unique. Your solution should fit your specific situation. Use FTA as a guide, but feel free to adapt it. The goal is to understand and solve your problems effectively.

The Purpose Behind Fault Tree Analysis

Using FTA helps you grow. You learn about problems and how they connect. This makes you a better problem-solver. It’s not just about fixing things. It’s about becoming more capable and confident.

By following these steps and understanding their purpose, you’ll be better prepared for future challenges. Keep in mind the importance of having a clear goal and taking purposeful action. This will lead you to success.

Pareto Chart: Focusing on What Matters

A Pareto Chart helps you see the most important issues clearly. It shows you the biggest problems so you can solve what matters most. Let’s dive into how to use it.

What is a Pareto Chart?

Think of a Pareto Chart as a special kind of bar graph. This chart shows problems in order, from the biggest to the smallest. This way, it’s easier to see what needs attention first.

How to Create a Pareto Chart

Creating a Pareto Chart is simple if you follow these steps:

1. Collect Data

First, gather data about your problems. The more detailed, the better.

2. Sort the Data

Next, arrange your data from the biggest issue to the smallest. This helps you see which problems are most important.

3. Draw the Chart

Make a bar for each problem. The tallest bar goes first, and the shortest one goes last. Add a line to show the total percentage each bar represents.

4. Analyze the Chart

Look at the chart. See which problems are the biggest. Focus on fixing those first.

Pros and Cons of Pareto Chart

Like any tool, using a Pareto Chart has its good and bad points. It’s important to know both sides.

Pros

1. Clear Priority: It shows which problems you should fix first. This helps you focus your efforts.

2. Simple to Understand: It’s easy to read. Even kids can get it.

3. Effective Visual Aid: It helps you see the data at a glance. This makes decision-making easier.

4. Encourages Efficiency: You tackle the biggest issues first, saving time and resources.

Cons

1. Needs Accurate Data: The chart is only as good as the data you collect. Inaccurate data can mislead you.

2. May Overlook Smaller Problems: Focusing on big problems might make you miss smaller but still important issues.

3. Possible Misinterpretation: Without understanding, you might not use the chart correctly.

Why Use a Pareto Chart?

Using a Pareto Chart is all about being efficient and effective. It helps you see where to put your effort to make the biggest impact. This means you solve problems faster and smarter.

Finding Your Own Solutions

Remember, everyone’s problems are different. Use the Pareto Chart to see what’s most important to you. Adapt it to fit your needs. The goal is to solve your unique problems effectively and efficiently.

The Purpose Behind Using a Pareto Chart

For you, using a Pareto Chart is about more than solving problems. It’s about prioritizing your actions and becoming a better leader. You learn which battles to fight first. This makes you smarter and more capable.

By using Pareto Charts with purpose, you grow in your leadership and problem-solving skills. Keep your focus on what matters most. This will lead you to success.

DMAIC: A Roadmap to Improvement

Let’s explore DMAIC, a powerful method for solving problems and improving processes. When you understand and use it, you can make great changes.

What is DMAIC?

DMAIC stands for Define, Measure, Analyze, Improve, and Control. It’s a step-by-step approach to tackle issues and bring about improvements.

Steps of DMAIC

Let’s break down each step so you can use it for your own problems.

1. Define

Clearly define the problem. Be specific about what needs fixing. Understanding the issue is the first step to solving it.

2. Measure

Gather data on the current process. This helps you see what’s really happening. Accurate measurements are key.

3. Analyze

Look at your data. Find the root causes of the problem. Understanding why something happens helps you find the right solution.

4. Improve

Develop and test solutions based on your analysis. Implement the best one. This step is all about making things better.

5. Control

Ensure the improvements stick. Put controls in place to maintain the changes. This helps prevent the problem from coming back.

Benefits of DMAIC

Using DMAIC offers several advantages. It’s a way to approach problems logically and systematically.

1. Structured Approach

DMAIC gives a clear structure to follow. This makes solving problems more manageable.

2. Data-Driven

By focusing on data, you make informed decisions. This leads to better outcomes.

3. Continuous Improvement

DMAIC is all about ongoing improvement. It encourages you to keep making things better.

4. Empowers Individuals

Following DMAIC helps you grow and learn. It gives you tools to solve your problems efficiently.

Challenges of DMAIC

While DMAIC is powerful, it’s not without challenges. Being aware of these can help you navigate them.

1. Time-Consuming

It can take time to go through all the steps thoroughly. Patience and persistence are important.

2. Requires Accurate Data

Inaccurate or incomplete data can lead to wrong conclusions. Collecting good data is crucial.

3. Needs Commitment

DMAIC requires dedication. You need to commit to the process to see results.

Personalizing DMAIC

Remember, DMAIC is flexible. Adapt it to fit your situation. Everyone’s problems are unique, and your approach should be, too. Use it to create solutions that work for you.

The Purpose Behind DMAIC

Using DMAIC is more than just solving problems. It’s about becoming a better leader and thinker. By following these steps, you not only fix issues but also create lasting improvements.

Focus on each step with purpose. This will guide you to meaningful changes. Through DMAIC, you grow and develop your leadership and problem-solving skills. Trust the process, and it will lead you to success.

FMEA: A Tool for Anticipating Problems

Failure Modes and Effects Analysis, or FMEA, is a method to predict and prevent problems before they happen. It’s about being proactive and ready for anything.

What is FMEA?

FMEA stands for Failure Modes and Effects Analysis. This tool helps you identify potential failures in a process or product. By knowing what could go wrong, you can take steps to avoid it.

Steps of FMEA

Let’s go through the FMEA process. It’s designed to help you foresee and prevent issues.

1. Identify Potential Failures

List all the things that could go wrong. These are the failure modes. Think about every possible scenario.

2. Determine Effects

Next, think about the effects of each failure. What happens if this failure occurs? Understanding the impact is crucial.

3. Assign Severity

Rate the severity of each effect. How serious is it? A simple scale helps. For example, from 1 (not serious) to 10 (very serious).

4. Analyze Causes

Identify causes of each failure. Why might each failure happen? Knowing the root causes helps you address problems effectively.

5. Assign Occurrence

Rate how likely each cause is to happen. Use a scale from 1 (unlikely) to 10 (very likely). This step helps focus on the most probable issues.

6. Identify Controls

What controls are currently in place to prevent the causes? List them. Effective controls reduce the chance of failures.

7. Assign Detection

Rate how likely it is that you’ll detect each failure before it occurs. Use a scale from 1 (very likely) to 10 (not likely). Good detection measures help catch issues early.

8. Calculate RPN

Calculate the Risk Priority Number (RPN) for each failure mode. Multiply severity, occurrence, and detection ratings. RPN helps prioritize which problems to tackle first.

Benefits of FMEA

FMEA offers several advantages. It’s a comprehensive way to manage risks.

1. Comprehensive Risk Assessment

FMEA provides a thorough look at potential problems. It leaves no stone unturned.

2. Preventive Action

By identifying issues early, FMEA helps you take preventive action. This saves time, money, and stress later.

3. Improved Processes

Using FMEA improves your processes. It helps you make things safer and more reliable.

4. Empowers Individuals

FMEA empowers you to take control. You can foresee problems and find your own solutions.

Challenges of FMEA

FMEA isn’t perfect. Understanding its challenges can help you use it better.

1. Time-Intensive

FMEA can take time to complete. It requires detailed analysis and thorough thinking. Patience pays off here.

2. Needs Accurate Information

Accurate information is key. Wrong data leads to wrong conclusions. Ensure your data is reliable.

3. Requires Team Effort

FMEA works best with input from different people. It’s a team effort. Encourage collaboration to get the best results.

Individualizing FMEA

Your approach to FMEA should fit your situation. Each problem and process is unique. Customize FMEA to meet your needs and find solutions that work for you.

The Purpose Behind FMEA

FMEA is more than just a tool. It’s a mindset. It’s about anticipating problems and taking purposeful action to prevent them.

Use FMEA to grow your skills in leadership and problem-solving. By being proactive, you not only manage risks but also become a stronger, more effective leader.

Remember, the key to FMEA is purpose. Approach each step with a clear goal in mind. This will guide you toward meaningful, lasting improvements. Trust the process, and it will lead you to success.

Understanding Scatter Diagrams: Finding Patterns in Data

A scatter diagram is a powerful tool for making sense of data. It helps you see patterns and relationships, guiding you toward smarter decisions.

What is a Scatter Diagram?

A scatter diagram is a type of graph. It shows data points on a chart, where each point represents two pieces of information. By looking at these points, you can see if there’s a connection between the variables.

How to Create a Scatter Diagram

Making a scatter diagram involves a few simple steps. Let’s break it down.

1. Collect Data

First, gather your data. You need pairs of values for each item you’re analyzing. For example, you might collect data on height and weight.

2. Draw Axes

Draw two lines to form a cross. Label one line for the first value (like height) and the other line for the second value (like weight).

3. Plot Data Points

Mark a point on the chart for each pair of values. Place the points where the values intersect.

4. Observe Patterns

Look at the scatter diagram. Do you see any trends? Patterns help you understand the relationship between the variables.

Benefits of Scatter Diagrams

Scatter diagrams offer clear advantages. They make complex data easy to grasp.

1. Visual Clarity

Seeing data as a scatter diagram is simple and clear. You quickly spot trends and outliers.

2. Identifies Relationships

Scatter diagrams show if there’s a link between two variables. This helps in making informed decisions.

3. Easy to Use

Creating and reading scatter diagrams is straightforward. You don’t need special skills, just basic data points.

4. Enhances Problem-Solving

Understanding patterns improves problem-solving. It helps you make better choices based on data.

Challenges of Scatter Diagrams

While useful, scatter diagrams have limitations. Being aware of these helps you use them effectively.

1. Requires Accurate Data

Scatter diagrams need correct data. Inaccurate information leads to wrong conclusions. Double-check your data.

2. Limited to Two Variables

Scatter diagrams only show relationships between two values. For more variables, consider other tools.

3. Patterns Aren’t Always Clear

Sometimes, patterns aren’t obvious. Data might appear random. Don’t force conclusions; look for real trends.

Individualizing Scatter Diagrams

Your approach to using scatter diagrams should suit your needs. Customize your chart to reflect your unique situation. This makes it easier to find meaningful insights.

The Purpose Behind Scatter Diagrams

Remember, scatter diagrams are about more than just plotting points. They’re a way to see correlations and make purposeful decisions.

Use scatter diagrams to sharpen your skills in leadership and problem-solving. By visualizing data, you gain a deeper understanding and can act with confidence.

Approach each scatter diagram with intention. Know what you’re looking for and take action based on what you find. This practice will guide you toward growth and success.

Free Root Cause Analysis Software

There are many software programs out there that will help ease you through the process of problem-solving. These free root cause analysis software programs can be extremely helpful in your problem-solving efforts.

Sologic offers some great root cause analysis software. This includes “5 Why’s” templates and a Fishbone Diagram tool.

Tap Root is another site that offers patented root cause analysis tools. Their root cause analysis software can either be utilized online or purchased and used onsite.

Think Reliability offers a free cause mapping root cause analysis template to make your process easier.

Root Cause Analysis is Not Only for Problem-Solving

Many times we focus on why a problem happened, but it’s just as important to understand why successes happen. Root cause analysis can and should be used on your big successes too. It’s the same type of steps. Start with the success and work your way back. Determining what caused it. This can help you replicate successes in the future.

Final Thoughts

Now you have the free root cause analysis tools to get to the root of any problem. The important part, when faced with a problem, is to try to get as much information as possible. The more information you have, the easier it will be to solve the problem.

Did you enjoy this article on root cause analysis tools and techniques? Please share using the buttons below and check out some other great personal and professional development articles here on Growth Tactics.